VISION WIDE TECH CO., LTD.

- Address: No. 1126-2, Bishan Rd., Caotun Township, Nantou 54258, Taiwan

- Tel: 886-49-2338888

- Fax: 886-49-2330083

- mail: info@visionwide.com.tw

- Privacy Policy

- 2018 Vision Wide Tech All Right Reserved

Extremely Mighty Machining Center

- Home

- Products

- Extremely Mighty Machining Center

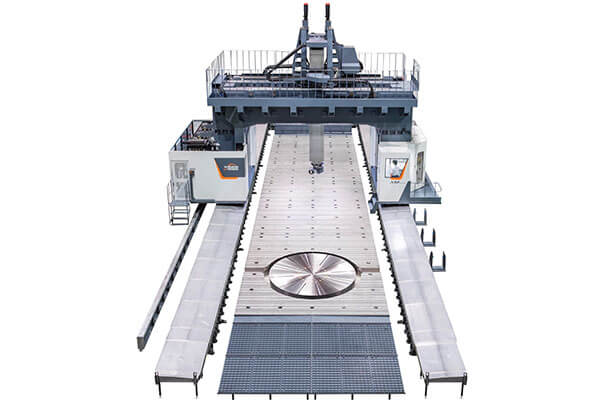

- Extremely Mighty Machining Center XMS Series

XMS Series

-

High Performance and Wide Application

XM series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:- Huge workpiece machining space:For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

- High-precise positioning:The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining.

- Heavy cutting capacity:Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

- Fully automatic multi-face machining:It can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

- Milling and turning compound multitask:This machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.

-

Model 單位 XMS-37 XMS-42 XMS-52 X axis travel mm 8,200(+1m)~60,200 Y axis travel mm 3,700 4,200 5,200 Z axis travel mm 2,000 (1,500/1,800/2,200 Opt.) Distance from spindle nose to table Ram size mm 580x580 Z axis=1,500 mm 1,000~2,500 Z axis=1,800 mm 700~2,500 Z axis=2,000(STD.) mm 500~2,500 Z axis=2,200 mm 500~2,700 Max. workpiece width mm 4,100 4,600 5,600 Table size mm 3.5 x 8~60 m 4 x 8~60m 5 x 8~60m Max. table load kg/m2 5,000 Spindle power (cont. / 30 min.) KW 22/26 Spindle speed 2-step gear rpm 4,000/6,000 (Opt.) Built-in Motor rpm 8,000 (Opt.)/12,000 (Opt.) Cutting feed rate mm/min 1-10,000 Rapid traverse(X/Y/Z) m/min 20/20/12 Tool magazine capacity pcs 32/40 (Opt.)/60 (Opt.) ※Please contact sales for more details.

-

Standard Accessory & Function- Fanuc 0iMF PLUS controller

- 4,000rpm 2-step gear type spindle

- Spindle oil cooler

- Z axis travel: 2,500 mm

- X Dual linear scale /Z axis linear scale

- Y axis Ballscrew supporting device

- Vertical type tool magazine 32 tools

- Centralized auto lubrication system

- Independent lubrication oil collector

- Air blast through spindle

- Wash gun & pneumatic interface

- Cutting coolant system

- Four piece sheet metal guard

- Wireless manual pulse generator

- Confrontable operation room

- Screw type chip conveyor on table sides

- Caterpillar type chip conveyor / Water tank

- Air conditioning for electrical cabinet

- Working lamp

- Operation cycle finish and alarm light

- Footswitch for tool clamping

- RJ45 interface

- XYZ-axis travel hard limits protection

- Auto power off

- Remote monitoring software-standard

- Vision Wide FX graphical user interface

- Foundation pads and bolts kits

- Adjustment tool and tool kits

- Technical manuals(operation, maintenance manual and circuit diagram)

Optional Accessory & Function- Fanuc 31iB controller

- HEIDENHAIN TNC640 controller

- SIEMENS 840D controller

- 6,000 rpm box way type 2-step gear spindle

- 8,000rpm Built-in spindle

- 12,000rpm Built-in spindle

- Z axis travel : 3,000mm

- Y axis linear scale

- Z axis hydrostatic guideway

- Without Tool magazine

- Vertical type tool magazine 40T / 60T

- Vertical-horizontal type tool magazine 32T/40T/60T

- Coolant through spindle system 20/70 bar

- Oil skimmer

- Oil mist cooling device

- Spindle ring cutting coolant device (for no head attachment)

- Z-axis retract function at power failure

- Helical bladed screw conveyor on table sides

- Chip cart

- Sub working table

- Auto tool length measurement

- Auto workpiece coordinate measurement

- Interface reserved for fourth axis

- Transformer

- AC attachment head

- Multi-heads magazine

- Anti-collision and proecess simulation software

- Remote monitoring software-standard

-

XMS Series

XM-Workpiece Cutting