VISION WIDE TECH CO., LTD.

- Address: No. 1126-2, Bishan Rd., Caotun Township, Nantou 54258, Taiwan

- Tel: 886-49-2338888

- Fax: 886-49-2330083

- mail: info@visionwide.com.tw

- Privacy Policy

- 2018 Vision Wide Tech All Right Reserved

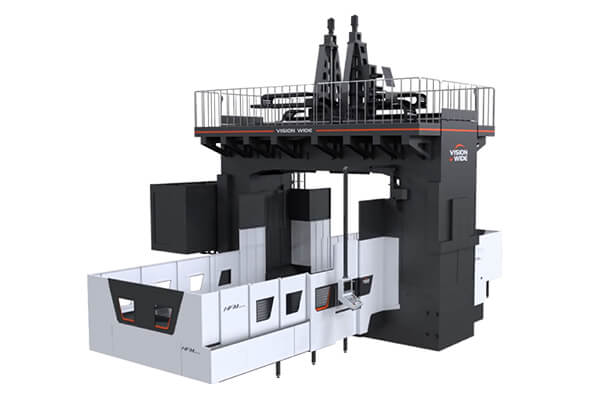

5-face Double Column Machining Center

- Home

- Products

- 5-face Double Column Machining Center

- HFM Series

HFM Series

-

HFM series is Vision Wide designed for ultra-large workpiece machining, which fulfills automatic 5-face machining with super rigidity structure and high positioning accuracy, satisfies demands in heavy cutting ability, angles cutting, 3D mold cutting, and precise contour finishing.

We developed tool center point compensation, auto multi-angle head attachment, and auto tool change system to complete auto 5-face machining.

- Crossbeam design with a box-in-box structure can reduce deformation caused by Z-axis loaded on the unilateral cross beam.

- The gravity center of the head is located on the centerline of the symmetric structure, the design can reduce the influence of ambient temperature.

- Head adopts hydrostatic transmission design which provides better rigidity, low friction, and stability for large Z-axis travel machines.

- 1,500~2,000Nm Spindle Torque output.

-

Model Unit HF-6042M HF-8042M HF-10042M HF-6047M HF-8047M HF-10047M X axis travel mm 6,100 8,100 10,100 6,100 8,100 10,100 Y axis travel mm 4,200 4,700 Z axis travel mm 1,500 1,500 Table size mm 6,000×3,000 8,000×3,000 10,000×3,000 6,000×3,500 8,000×3,500 10,000×3,500 Max. table load kg 28,000 32,000 36,000 28,000 32,000 36,000 Spindle power (cont. / 30 min.) kW 22/26 (30/37 Opt.) 22/26 (30/37 Opt.) Spindle speed Linear way & enclosed box ram / dual ballscrews 2-step gear rpm 4,000/6,000 (Opt.) 4,000/6,000 (Opt.) Direct-driven rpm 10,000 (Opt.) 10,000 (Opt.) Cutting feed rate mm/min 1~7,000 1~7,000 Rapid traverse X/Y/Z (Linear way) 15/15/15 15/15/15 15/15/15 15/15/15 15/15/15 15/15/15 X/Y/Z (Box way) m/min 15/15/12 15/15/12 15/15/12 15/15/12 15/15/12 15/15/12 ※Please contact sales for more details.

-

Standard Accessory & Function- SIEMENS ONE controller

- Z axis travel 2,000mm (Linear way)

- 2-step gear type spindle 4,000rpm

- Z axis linear scale feedback

- Z axis Twin Servo driver

- Spindle cooling system

- Centralized auto lubrication system

- Independent lubrication oil collector

- Air blast through spindle

- Wash gun and pneumatic interface

- Cutting fluid cooling system

- Four piece sheet metal splash guard

- Swiveling arm type operation panel

- Screw type chip conveyor on table sides

- Caterpillar type chip conveyor / Water tank

- Heat exchanger for electrical cabinet

- Working lamp

- Operation cycle finish and alarm light

- Movable manual pulse generator

- Footswitch for tool clamping

- RJ45 interface

- XYZ axis absolute pulse coder feedback

- XYZ axis travel hard limits protection

- Foundation pads and bolts kits

- Adjustment tool and tool kits

- Technical manuals (operation, maintenance manual and circuit diagram)

Optional Accessory & Function- SIEMENS ONE controller

- Z axis travel 2,500/ 3,000/ 3,500/ 4,000mm (Linear way)

- 2-step gear type spindle 6,000rpm

- Vertical type tool magazine 40tools

- X/Y-axis linear scale feedback

- Transformer

- Air conditioning for electrical cabinet

- Hanging tools and fixtures for installation

- Switch for tool clamping