VISION WIDE TECH CO., LTD.

- Address: No. 1126-2, Bishan Rd., Caotun Township, Nantou 54258, Taiwan

- Tel: 886-49-2338888

- Fax: 886-49-2330083

- mail: info@visionwide.com.tw

- Privacy Policy

- 2018 Vision Wide Tech All Right Reserved

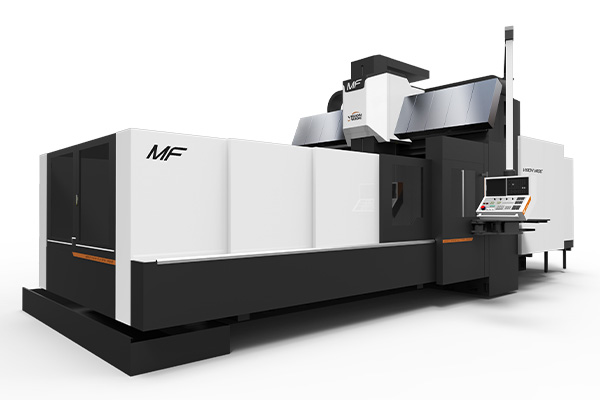

MF Series Milling Machine

- Home

- Products

- Double Column Milling Machine

- MF Series Milling Machine

MF Series

-

- MF series bridge type machines, with typical VW products features of rigid structure and high precision, are designed with box ways with hand scrapping, slant beam with three ways, direct-driven Y-Z transmission, to get the heavy cutting and precision cutting with high acceleration/deceleration control. It's the best choice for medium-to-large parts and mold machining.

- Z-axis is at the symmetrical position of the spindle motor, offering accuracy and precision with micro smooth movement. Using Japan-made JIS0 gears for the gear head to get the advantages of high rigidity, high precision, and low noise.

- 3 axes independent ball-screw cooling device.

- Solid casting structure, providing good mechanical static and dynamic accuracy.

- 65-degree slant beam device, with 3-sliding ways, provides strong support to the headstock. It offers the best performance for heavy cutting compared to others with the same column distance.

- The direct-driven device on Y-Z axis transmission, with big servo motors, ensures the best accuracy and acceleration.

- X-axis power transmission with gear reducer device offers servo motor high precision control and enhances the 2-4 times of driving torque. (MF/MN/MH)

- An independent cooling device for 3-axes ball crews well restrains the axial heat extension. (MB/MF)

- Separated oil coolers for spindle and 3-axes ball screws, with temperature setting -2 °C lower than room temperature, well control the heat deformation when machining. (MB/MF)

-

Model Unit MF-3000 MF-4000 MF-5000 MF-3026 MF-4026 MF-5026 X axis travel mm 3,200 4,200 5,200 3,200 4,200 5,200 Y axis travel mm 2,300 2,600 Z axis travel mm 920/1,020(Opt.) 920/1,020(Opt.) Table dimension mm 3,200x2,050 4,200x2,050 5,200x2,050 3,200×2,050 4,200x2,050 5,200x2,050 Max. table load kg 11,000 13,000 15,000 11,000 13,000 15,000 Spindle motor power

(cont./ 30 min rated)kW 18.5/22(22/26Opt.) (30/37Opt.) 18.5/22(22/26Opt.) (30/37Opt.) Spindle speed rpm 4,000/6,000(Opt.) 4,000/6,000(Opt.) Cutting federate mm/min 1-7,000 1-7,000 Rapid traverse (X/Y/Z) m/min X/Y/Z:12 X:10 Y/Z:12 X/Y/Z:12 X:10 Y/Z:12 ATC capacity pcs 40/60(Opt.) 40/60(Opt.) ※Please contact sales for more details.

-

Standard Accessory & Function- Fanuc 0iMF PLUS Controller

- 4,000 rpm two-step gear spindle

- Spindle oil cooler

- Twin hydraulic cylinders with pressured air assistance balancing system

- X-axis ball screw supporter ( X > 4m above)

- Centralized auto lubrication system

- Independent lubrication oil collector

- Ball screw cooling system

- Air blast through spindle

- Wash gun and pneumatic interface

- Cutting fluid cooling system

- Enclosed sheet metal guard without roof

- Swiveling arm type operation panel

- Screw type chip conveyor on table side

- Caterpillar type chip conveyor / Water tank

- Heat exchanger for electrical cabinet

- Working lamp

- Operation cycle finish and alarm light

- Movable manual pulse generator

- Footswitch for tool clamping

- RJ45 interface

- XYZ-axis absolute pulse coder feedback

- XYZ-axis travel hard limits protection

- Spindle cutting load software protection

- Remote monitoring software-Standard

- Auto power off

- Vision Wide FX graphical user interface

- Foundation pads and bolts kits

- Adjustment tool and tool kits

- Technical manuals (operation, maintenance manual and circuit diagram)

Optional Accessory & Function- 6,000 rpm 2-step gear spindle

- Z-axis travel 1,020mm

- 200/300/400/500 mm higher column

- Interface preparation for coolant through spindle system

- Coolant through spindle system 20/70 bar

- Coolant through tool holder interface

- Coolant through tool holder 5 bar /20 bar cutting fluid interface

- Oil skimmer

- Oil mist cooling device

- Spindle ring cutting coolant device ( for no head attachment)

- 40/60 tools magazine with arm type ATC

- Enclosed splash guard with roof

- Chip auger on table side

- Chip cart

- Air conditioner for electrical cabinet

- XYZ-axis linear scale feedback

- 3-axis independent manual pulse generator

- Sub table

- Rotary table

- Interface reserved for fourth axis

- Z-axis retract function at power failure

- Anti-collision and machining simulation software

- Remote monitoring software-Professional (Not available for Siemens controller)

- Automatic tool length measurement

- Auto workpiece coordinate measurement

- Transformer

- Auto warm up

-

MF Series