VISION WIDE TECH CO., LTD.

- Address: No. 1126-2, Bishan Rd., Caotun Township, Nantou 54258, Taiwan

- Tel: 886-49-2338888

- Fax: 886-49-2330083

- mail: info@visionwide.com.tw

- Privacy Policy

- 2018 Vision Wide Tech All Right Reserved

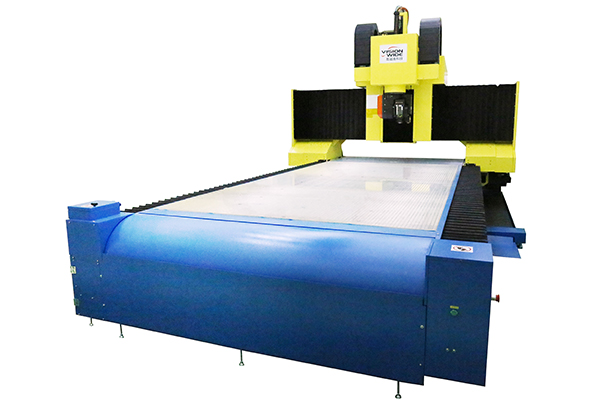

Ultrasonic Machining Center

UC Series

-

UC Series, an ultrasonic machining center, is mainly designed for aerospace honeycomb structure processing and it can efficiently perform honeycomb structure cutting with different inclinations, and output various structural shapes that meet customer needs.

- Composite paper honeycomb angle processing – triangle cutter processing and disc cutter processing

- With the lightweight and dynamic column structure, combined with precision gears and racks, the movement is fast, ensuring the best feed speed.

- Oil-free pollution processing of advanced materials, and the three-axis slide rail adopts a full grease lubrication device.

- Using European standard precision gear transmission on feeding axis to be provided with high feed rigidity position accuracy.

- Feeding axis with high accuracy linear scale feedback to use low thermal deformation coefficient to control positioning accuracy on a linear scale.

- Feeding axes are using roller-type linear guideways to keep accuracy for the long term.

- Vacuum chuck is clamping device under vacuum table to make workpiece adsorb stably on the table.

- Two axis head self-monitoring protection system.

- Spindle cooling system.

- Auto workpiece coordinate measurement / Contacting auto tool length measurement / Triangular tool angle deviation measurement

As one of the professional composite material machining center makers, Vision Wide Tech always seeks to apply the latest manufacturing technology and design to provide the best processing solution for the aerospace industry. If you need high efficient and accuary ultrasonic five-axis machining centers, please don't hesitate to submit them to our Customer Service Center.

-

Model Unit UC-4020 X axis travel mm 4,000 Y axis travel mm 2,000 Z axis travel mm 550 Table dimension

(Length x Width)mm 4,000 x 2,000 Spindle speed rpm 24,000 Spindle motor power(S1/S6) kW 22 / 25 Ultrasonicator frequency Hz 20k±0.3K Rapid traverse(X/Y/Z) mm/min X,Y:40,000 Z:12,000 Cutting federate mm/min X,Y,Z:12,000 ATC capacity pcs 7 ※Please contact sales for more details.

-

Standard Accessory & Function- HEIDENHAIN TNC640 controller

- 24,000 HSK-A63 Spindle

- ATC (auto tool change) (7 tools )

- Air blast through spindle

- Switch for tool clamping

- Independent lubrication oil collector

- Centralized auto lubrication system

- Floor-standing type operation panel

- Movable manual pulse generator

- XYZ axis linear scale feedback

- XYZ-axis travel hard limits protection

- Vacuum system

- Cover fence

- Air conditioning for electrical cabinet

- Operation cycle finish and alarm light

- RJ45 interface

- Auto power off function

- Z-axis retract function at power failure

- Foundation pads and bolts kits

- Adjustment tool and tool kits

- Technical manuals(operation, maintenance manual and circuit diagram)

-

UC Series

UC-Ultrasonic Honeycomb Machining Center