- Address: No. 1126-2, Bishan Rd., Caotun Township, Nantou 54258, Taiwan

- Tel: 886-49-2338888

- Fax: 886-49-2330083

- mail: info@visionwide.com.tw

- Privacy Policy

- 2018 Vision Wide Tech All Right Reserved

- Reader Version

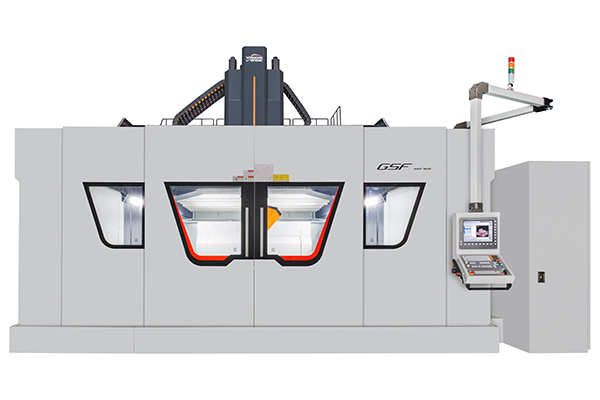

5-axis Gantry Type Machining Center

- Home

- Products

- Gantry Type Milling Machining Center

- 5-axis Gantry Type Machining Center GSF Series

GSF Series

-

GSF Series 5 axis gantry type machining center, provided excellent 5-axis simultaneous accuracy performance for 5-axis machining in mold cutting, highly precise contour finishing, milling, drilling, and tapping. Vision Wide manufactured this gantry 5 axis cnc machine to shorten tool displacement travel and cutting process effectively and extend tool life and offer the best choice for composite angle machining. GSF Series 5 axis gantry mill had an excellent dynamic performance on one-piece structural and equipped high accuracy 2-axis head to achieve 5-axis simultaneous accuracy performance.

- Continuous 2-axis head

- 5 axis dynamic rotation synchronization accuracy (TCPM) 0.04mm.

- Built-in Spindle Direct-Driven on B&C axis, 15,000rpm spindle speed.

- Backlashless driving on B/C axis, Rotation Positioning accuracy ±5”.

- Low table height, closer operating zone, and wider door width are convenient designs for users.

- Chain type chip conveyor (standard) is able to remove iron chips efficiently.

Industries Applications:

- Aerospace-Aluminum Frame

- Automotive- Stamping Die

- Mechanical Component

-

Our GSF Series of Gantry 5 Axis CNC Machine offers a range of models to suit different requirements, Welcome to contact us to learn more about the Vision Wide GSF Series and how it can enhance your manufacturing capabilities.

Model Unit GSF-1627 GSF-2227 GSF-3027 GSF-4027 GSF-5027 GSF-6027 X axis travel mm 1,600 2,200 3,000 4,000 5,000 6,000 Y axis travel mm 2,700 Z axis travel mm 1,000/1,200 Table size mm 1,600 x 2,700 2,200 x 2,700 3,000 x 2,700 4,000 x 2,700 5,000 x 2,700 6,000 x 2,700 Max. table load kg/m2 3,000 Spindle power (S1/S6) kW 50/65 Spindle speed rpm 15,000 Cutting feed rate mm/min 1-20,000 Rapid traverse (X/Y/Z) m/min XY:32 / Z:20 Tool magazine capacity pcs 20/32/40/60

Model Unit GSF-2232 GSF-3032 GSF-4032 GSF-5032 GSF-6032 X axis travel mm 2,200 3,000 4,000 5,000 6,000 Y axis travel mm 3,200 Z axis travel mm 1,000/1,200 Table size mm 2,200 x 3,200 3,000 x 3,200 4,000 x 3,200 5,000 x 3,200 6,000 x 3,200 Max. table load kg/m2 3,000 Spindle power (S1/S6) kW 50/65 Spindle speed rpm 15,000 Cutting feed rate mm/min 1-20,000 Rapid traverse (X/Y/Z) m/min XY:32 / Z:20 Tool magazine capacity pcs 20/32/40/60 ※Please contact sales for more details.

-

Our 5 Axis Gantry Mill offers a wide range of standard and optional accessories to enhance your machining capabilities, including:

Standard Accessory & Function- HEIDENHAIN TNC640 controller

- HEIDENHAIN DCM (Dynamic Collision Monitoring)

- HST810x15,000 rpm/HSK-A100

- 2-axis head centeral monitoring protection system:

Spindle and motor temperature monitoring

B/C-axis motor temperature monitoring

Spindle cutting load software protection - 2-axis Head rotation error mechanism chain correction

- Z-axis travel 1,000 mm

- Spindle and structure temperature thermal compensation system

- Air blast through spindle

- Spindle cooler system

- Spindle ring cutting coolant device

- Cutting fluid cooling system

- X axis ball screw support device (axis 4m above)

- X axis dual linear scale, Y/Z-axis linear scale

- XYZ-axis travel hard limits protection

- X/Z axis is driven by dual ballscrew and Y axis is driven by single ballscrew.

- Centerlized auto lubrication system

- Independent lubrication oil collector for 3-axis

- Wash gun & pneumatic interface

- Enclosed sheet metal guard without roof

- Vertical type tool magazine 20T

- Screw type chip conveyor on table sides

- Caterpillar type chip conveyor / Water tank

- Swiveling arm type operation panel

- Air conditioner for electrical cabinet

- Working lamp

- Operation cycle finish and alarm light

- Movable manual pulse generator

- RJ45 interface

- Footswitch for tool clamping/uncplamping

- Remote monitoring software-standard

- Auto power off function

- Tool axis retract function at power failure

- Foundation pads and bolts kits

- Adjustment tool and tool kits

- Technical manuals(operation, maintenance manual and circuit diagram)

Optional Accessory & Function- SIEMENS 840D SL controller

- HST810x12,000 rpm/HSK-A100

- HST810x24,000 rpm/HSK-A63

- HSD610x24,000 rpm/HSK-A63

- Automatic correction software of rotary axis error

- Spindle cutting vibration protection device

- Z-axis travel 1,200 mm

- Vertical type tool magazine 32T

- Coolant through spindle system:20/ 60 bars

- The interface of coolant through spindle

- Coolant through spindle system 20 / 60 bars+air through 6 bars

- Oil skimmer

- Oil mist cooling device

- Enclosed sheet metal guard with roof

- Helical blade screw conveyor on table sides

- Dual belt type chip conveyor / Water tank

- Foot pad above chip groove

- Chip cart

- Sub working table

- Auto tool length measurement

- Auto workpiece measurement

- Transformer

- Transformer and Voltage Stabilizer

- Oil mist recycle device

- Adaptive Feed Control (AFC)

- Auto warm up

- X/Y-Axis Linear Motor Drive

- Feedrate:60m/min

-

Watch Vision Wide's GSF Series 5 Axis Gantry Type CNC Machining Center video for how machining in industries applications. For more information, please contact us today!

GSF Series

GSF-Similar Compressor Case Verification Workpiece

GSF-Aircraft Wing Machining

GSF-Aerospace Structural Parts Machining